What Makes Chemical Defoamer Important for Managing Foam Issues

What Makes Chemical Defoamer Important for Managing Foam Issues

Blog Article

Checking Out the Advantages of a Chemical Defoamer in Production and Production

The assimilation of chemical defoamers in manufacturing and manufacturing procedures provides a calculated benefit by resolving one of the consistent challenges in industrial operations: foam control. As producers strive to optimize procedures and enhance client contentment, the role of chemical defoamers ends up being increasingly crucial.

Significance of Foam Control

While the visibility of foam in producing procedures can sometimes seem safe, efficient foam control is essential for maximizing operational effectiveness and product high quality. Foam can hinder numerous stages of production, resulting in ineffectiveness that may raise expenses and prolong handling times. In industries such as food and beverage, pharmaceuticals, and chemicals, unrestrained foam can block devices, disrupt automated systems, and eventually result in item incongruities.

Carrying out reliable foam control techniques not only boosts performance but likewise sustains governing conformity in industries where foam can result in ecological worries. By making use of chemical defoamers, makers can mitigate these difficulties, making sure smoother operations and higher-quality output. Inevitably, prioritizing foam control is a crucial aspect of manufacturing that can yield substantial benefits in terms of product, efficiency, and safety dependability.

Sorts Of Chemical Defoamers

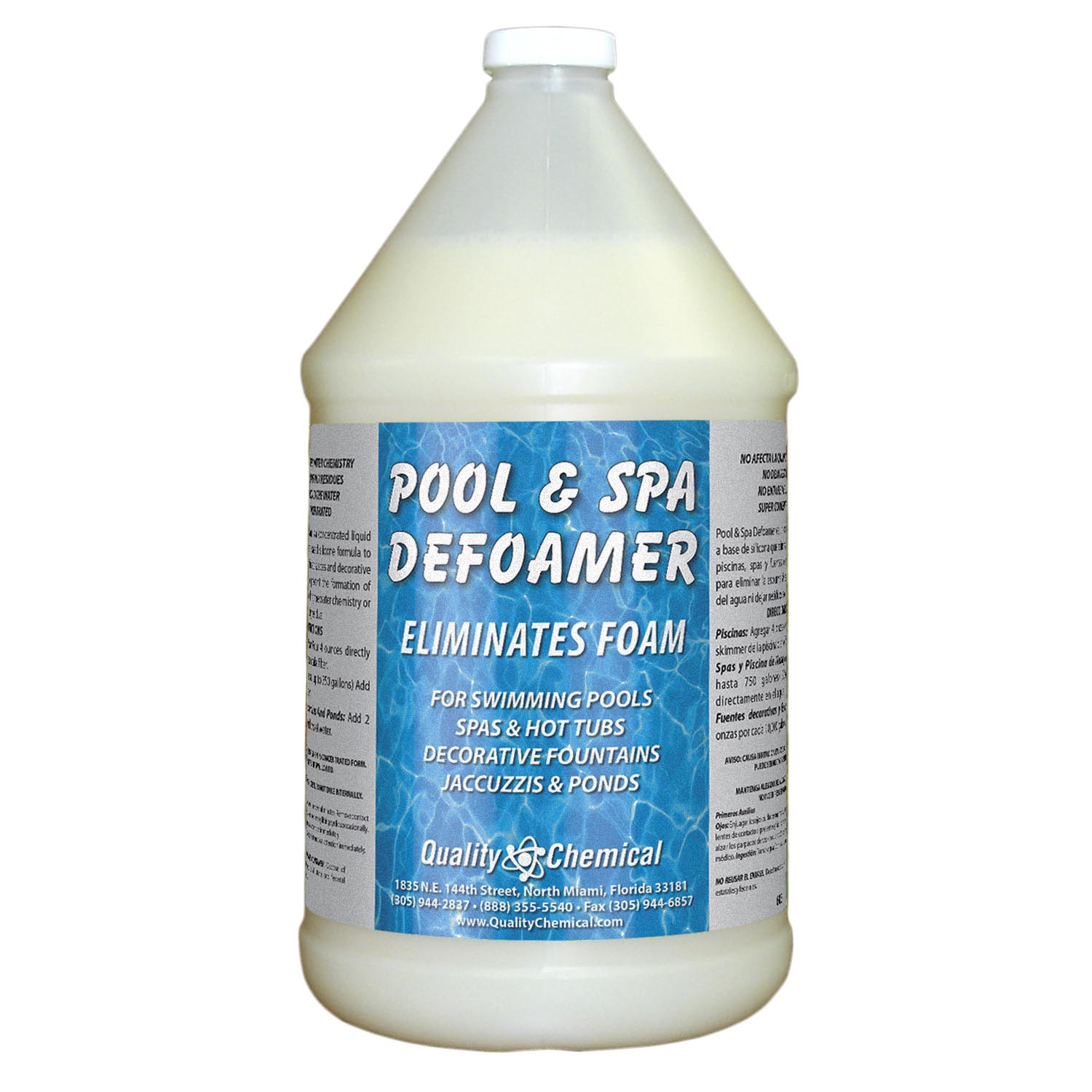

What kinds of chemical defoamers are available for making procedures, and exactly how do they differ in application? Chemical defoamers can be classified into three main types: silicone-based, organic, and not natural defoamers. - Chemical Defoamer

Organic defoamers, commonly originated from fatty acids or natural oils, are efficient in an array of applications, including food and beverage production. They are usually preferred for their lower poisoning and environmental effect, making certain compliance with market policies.

Each type of defoamer offers distinctive purposes based on the chemical composition and the specific needs of the manufacturing process, allowing suppliers to select the most ideal option for their specific requirements.

Benefits in Production Performance

Chemical defoamers play a crucial function in improving producing effectiveness by properly managing foam generation during numerous procedures. Foam can prevent manufacturing prices, interrupt tools operation, and cause expensive downtime. By incorporating chemical defoamers, suppliers can reduce these issues, making certain smoother process and boosted general performance.

The use of chemical defoamers assists maximize the operational performance of tools such as reactors, mixers, and pumps. With lowered foam, these equipments can run at their meant ability, decreasing the danger of overflow and enabling consistent processing. This causes better resource right here use and greater throughput.

Moreover, chemical defoamers help with faster handling times by lowering the time needed for foam removal. This acceleration can considerably influence production schedules, enabling manufacturers to satisfy client need better. Furthermore, making use of defoamers adds to lower power intake, as equipment operates more successfully with reduced foam interference.

Impact on Product Quality

Foam control is not only vital for preserving performance in making processes however likewise plays a substantial role in guaranteeing product quality. Excessive foam can present air into formulations, resulting in inconsistencies in the end product. This can show up as problems such as spaces, uneven textures, or poor finishes, which undermine the designated high quality and performance of the item.

Additionally, foam can hinder the homogeneity of mixtures, leading to unequal distribution of energetic ingredients. In markets such as finishings, cosmetics, and food production, this can result in variations in color, preference, and general performance. By utilizing a chemical defoamer, producers can alleviate these risks, ensuring that products satisfy strict quality requirements.

Additionally, regulating foam Visit Website can improve the stability of emulsions and suspensions, which is important for ensuring shelf-life and customer complete satisfaction. With improved product consistency and lowered flaws, suppliers can achieve higher criteria of high quality assurance, ultimately resulting in increased client trust and brand name loyalty.

Cost-Effectiveness and ROI

Reliable foam control not only boosts product top quality yet likewise contributes significantly to the total cost-effectiveness of making processes. Making use of chemical defoamers decreases foam-related issues, which can or else lead to manufacturing delays, equipment malfunctions, and raised energy usage. By decreasing foam, makers can maximize their procedures, leading to greater throughput and effectiveness.

Purchasing chemical defoamers can yield a considerable roi (ROI) The first expenses connected with these additives are usually countered by the cost savings understood from decreased downtime and improved product yield. Furthermore, improved item top quality can reduce waste and remodel costs, further reinforcing economic performance.

In enhancement, effective foam control can bring about minimized water and power usage, adding to reduced functional costs. This is particularly essential in markets where resource efficiency is vital. By incorporating chemical defoamers right into their procedures, makers can accomplish lasting financial savings while maintaining affordable rates in the industry.

Final Thought

In verdict, the assimilation of chemical defoamers in manufacturing and production procedures is crucial for maximizing functional performance and enhancing product top quality. The benefits provided by chemical defoamers not just support governing compliance but additionally provide an affordable edge in the manufacturing landscape.

The integration of chemical defoamers in production and production procedures uses a tactical advantage by resolving one of the consistent challenges in commercial operations: foam control.While the visibility of foam in producing procedures can occasionally seem safe, efficient foam control is essential for maximizing operational performance and product high quality.Chemical defoamers play an important duty in boosting producing efficiency by successfully controlling foam generation throughout various procedures.Furthermore, chemical defoamers assist in faster processing times by reducing the time needed for foam removal. In site here addition, the use of defoamers adds to decrease energy consumption, as machinery operates more successfully with reduced foam disturbance.

Report this page